© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 107

APPENDIX 2A

HELICAL PRODUCT RATINGS, PROPERTIES AND DETAILS

Chapter 2

Helical Foundation Systems

Plain

Plain

Corroded

(1)

Galvanized

Corroded

(1,2)

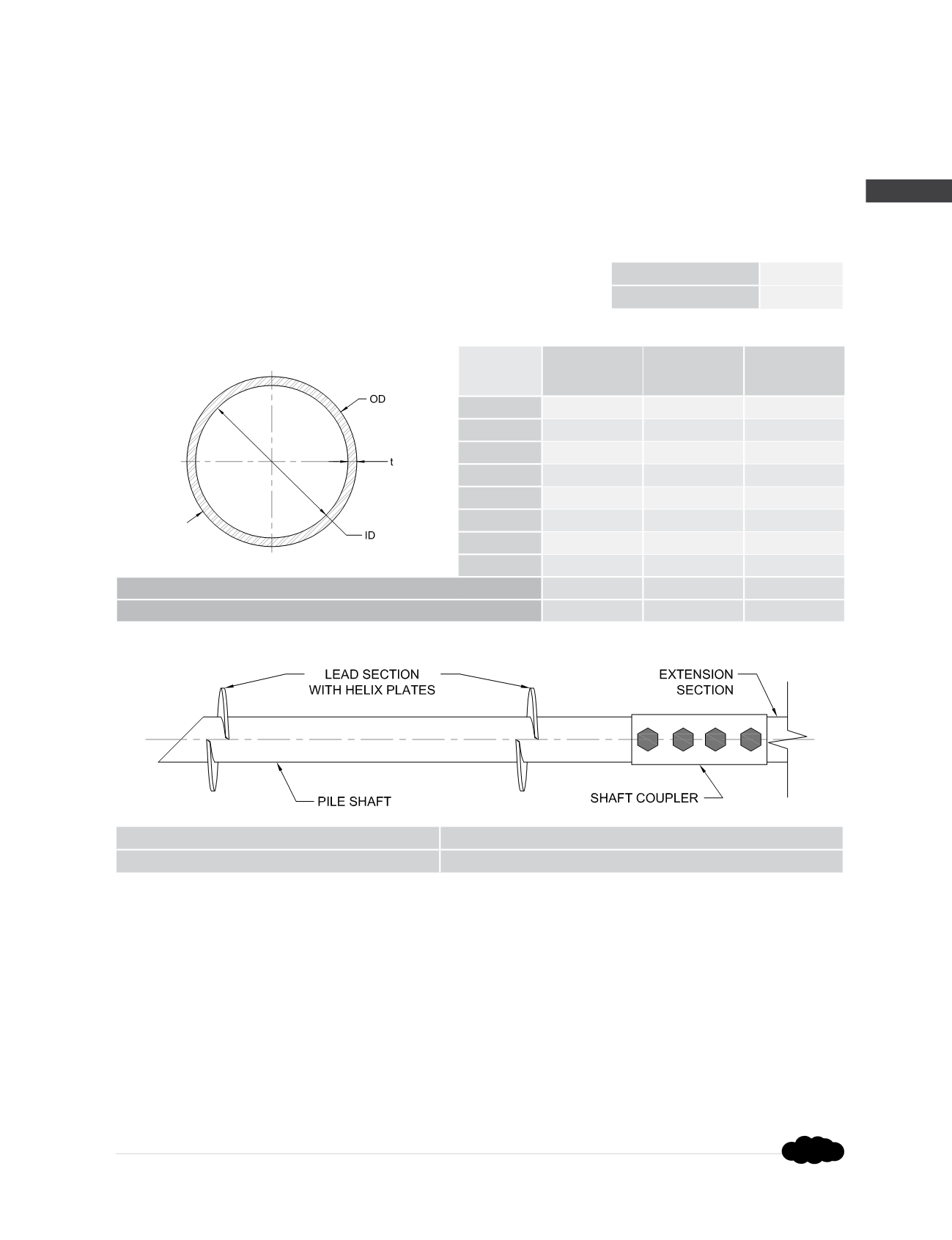

OD (in)

7.000

6.964

6.990

t (in)

0.337

0.301

0.327

ID (in)

6.326

6.362

6.336

A (in

2

)

7.05

6.30

6.84

I (in

4

)

39.25

35.04

38.08

S (in

3

)

11.21

10.06

10.89

Z (in

3

)

14.97

13.37

14.53

r (in)

2.36

2.36

2.36

Shaft Max Allowable Compression Capacity

(4,5)

P

n

/Ω (kips)

246.9

220.5

239.6

Shaft Max Allowable Tension Capacity

(5)

P

n

/Ω (kips)

135.0

118.8

130.5

HP700 Shaft Specifications and Capacities

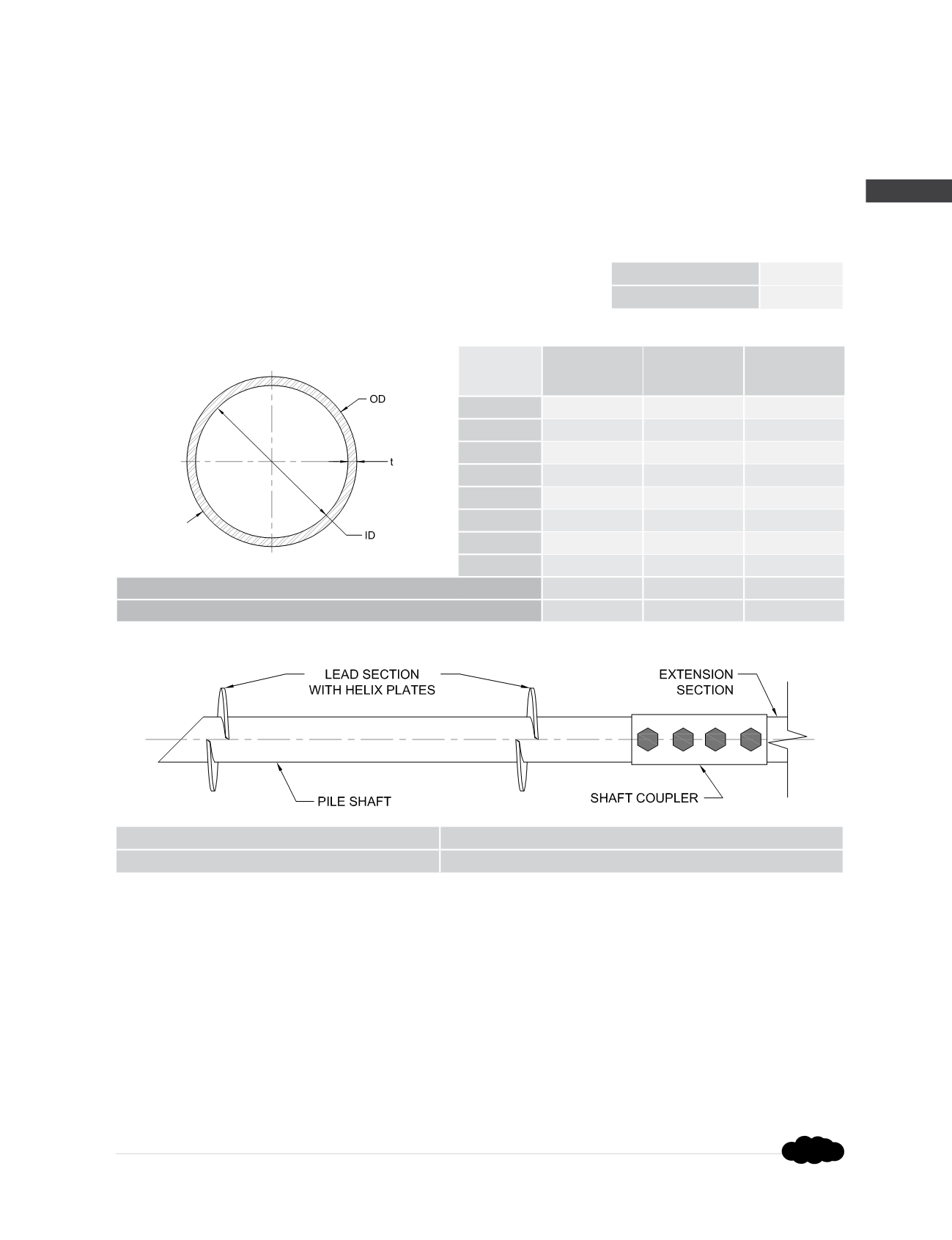

Shaft Material

(6)

:

Ø

7.000” x 0.362” wall

ASTM A252 Grade 3

Yield strength = 60 ksi (min)

Tensile strength = 70 ksi (min)

Shaft Coupler Material

(6)

:

Ø

7.750” x 0.313” wall

ASTM A513 Type 5 Grade 1026

Yield strength = 70 ksi (min)

Tensile strength = 80 ksi (min)

Helix Plates

(6)

:

ASTM A572 Grade 50 material

1

” thick (standard)

Helix plate geometry conforming to

ICC-ES AC358

Shaft Coupling Hardware

(6)

:

(4) -

Ø

2” ASTM A307 bolts with nuts

Electrozinc plated per ASTM B633

Surface Finish of Shaft

Segments:

Available plain or hot-dip galvanized

(2)

Nominal Thickness

0.362 (in)

Design Thickness

(3)

0.337 (in)

Torque Correlation Factor

(6)

K

t

= N/A (ft

-1

)

Maximum Ultimate Soil Capacity

(6)

Q

u

= N/A (kips)

Maximum Installation Torque

(6)

T = 50,000 (ft-lb)

Maximum Allowable Soil Capacity

(6)

Q

a

= N/A (kips)

(1)

Corroded properties and capacities include a 50-year scheduled sacrificial loss in thickness per ICC-ES AC358.

(2)

Hot-dip galvanized coating in accordance with ASTM A123.

(3)

Design thickness for HSS and Pipe based on 93% of nominal thickness per AISC.

(4)

Allowable mechanical compression capacities consider continuous lateral soil confinement in soils with SPT blow counts ≥ 4. Piles with

exposed unbraced lengths or piles placed in weaker or fluid soils should be evaluated on a case by case basis by the project engineer.

(5)

Listed mechanical capacities are for the shaft and coupled connections only. System capacity should also not exceed the installed allowable

soil capacity or the allowable capacity of the respective bracket (see additional bracket tables).

(6)

FSI’s larger diameter product lines are fully customized on a project specific basis. All values provided for these products are for general

informational purposes only. Actual capacities (including any related to installation torque) will vary based on several project specific variables

such as coupler details, end termination details, site specific soil profiles, and even material availability. Full scale load tests are recommended

to confirm soil capacities determined in the design phase of the project.

Rev. 8/21/14