© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 333

Chapter 5

PolyLEVEL

®

Polyurethane Foam and Resin

CHAPTER 5

POLYLEVEL

®

POLYURETHANE FOAM AND RESIN

CHAPTER 5

POLYLEVEL

®

POLYURETHANE FOAM AND RESIN

5.1 Summary Description

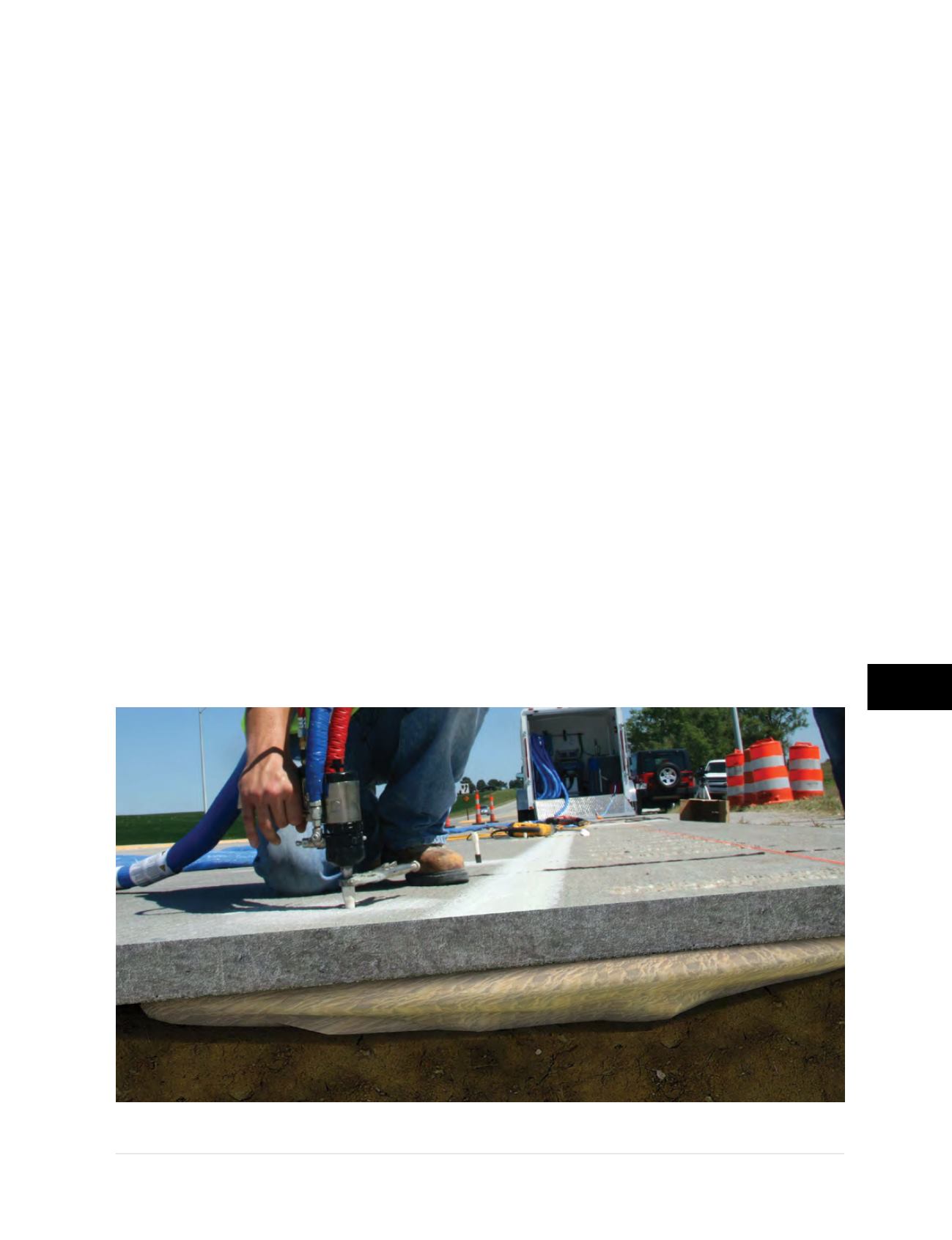

The PolyLEVEL product line consists of

polyurethane foams and resins for use in a

wide range of geotechnical and structural

applications. The more commonly used

products are two-part urethanes that expand

into rigid foam to fill voids, stabilize concrete,

and lift concrete. The product is injected at the

interface between the concrete slab and the

subgrade soils

(Figure 5.1.a)

. Variations in the

formulas of the two-part foams allow for uses in

even more specific applications, as mentioned in

Section 5.2. Outside of the general offerings of

two-part products, single-part, non-expanding

PolyLEVEL resin is injected deep into loose

soil as a binder material, thereby stabilizing the

soil from further consolidation/densification, or

allowing vertical excavations to be made.

Polyurethane is not a new material. The

chemistry of polyurethanes was discovered and

patented in 1937 and has been used extensively

for three quarters of a century in a variety of

products and materials. Polyurethanes are

best known to the public in the form of flexible

foams; i.e., upholstery cushions, mattresses,

caulking, weatherstripping, vehicle door and

dash moldings, tires for toddler bikes and

wheelborrows, etc. Spray foam insulation

and foam filler within shells of watercraft are

examples most similar to the line of two-part

PolyLEVEL products.

Polyurethane foam is created by the reaction

of a diisocyanate (the “A” or “Iso” side) with

a polyol (the “R” or “Resin” side) to form a

urethane linkage. Diisocynates are organic

compounds that are specifically manufactured

to react with polyols. The A side varies little

between polyurethanes of similar product lines

or use groups. Polyols are simply alcohols with

multiple hydroxyl groups. The polyols and other

additives within the R side may vary significantly

between products to control characteristics

such as color, density and speed of reaction.

Figure 5.1.a

Rendering of PolyLEVEL foam

injection beneath concrete pavement