© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 7

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.3 – Helical Foundation

System Components

2.3.1 – Helix Plates

The initial installation of a helical pile is performed

by applying downward force (crowd) and rotating

the pile into the earth via the helix plates. Once

the helix plates penetrate to a depth of about

two to three feet, the piles generally require less

crowd and installation is accomplished mostly

by the downward force generated from the helix

plates, similar to the effect of turning a screw

into a block of wood. Therefore, the helix plate

performs a vital role in providing the downward

force or thrust needed to advance the pile to

the bearing depth. The helix plate geometry

further affects the rate of penetration, soil

disturbance and torque to capacity correlation.

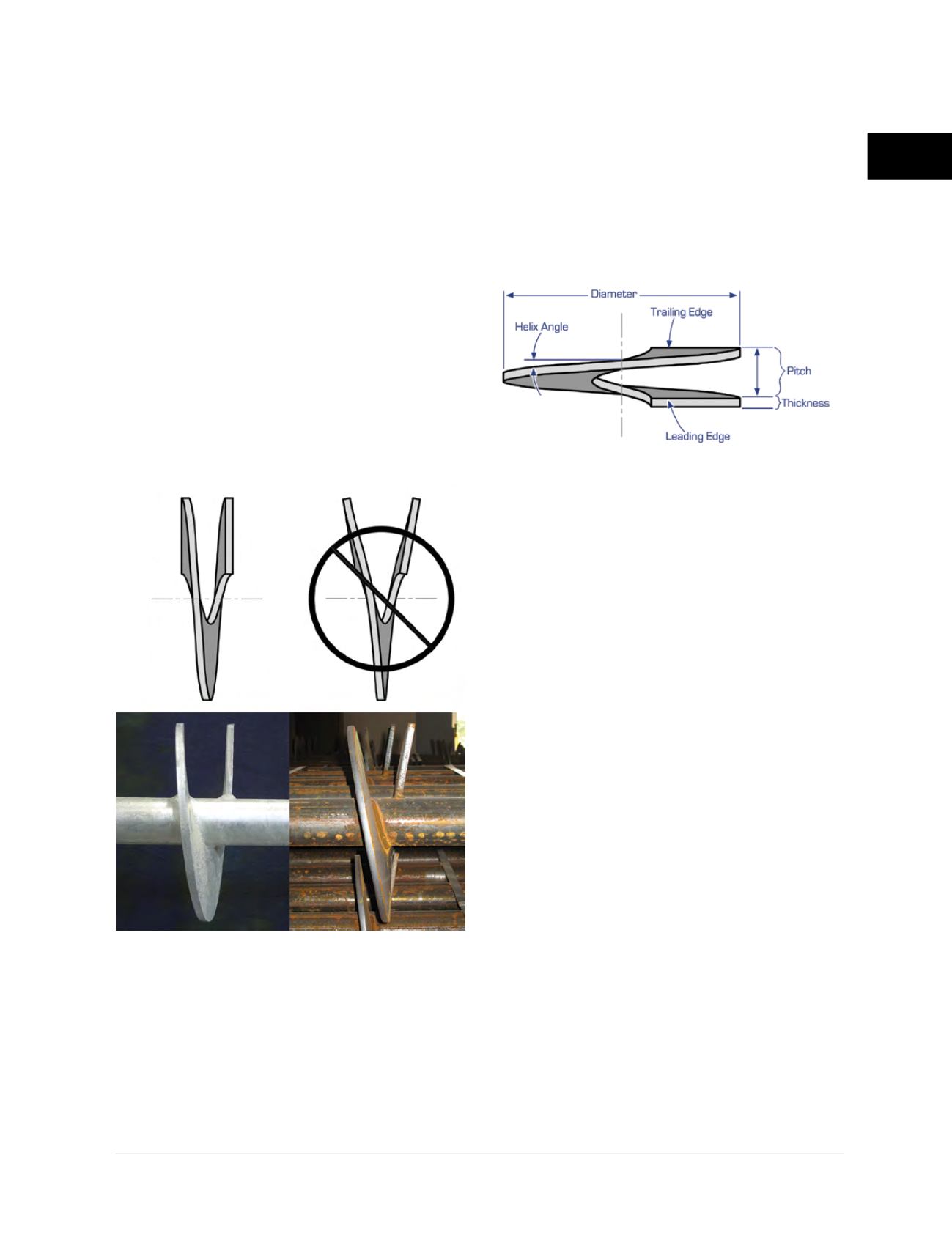

The consequences of a poorly-formed helix are

twofold; (1) the helix plate severely disturbs the

soil with an augering effect which (2) directly

results in more movement upon loading than a

pile with well-formed helices. The differences

between a well-formed helix and poorly-formed

helix are visually obvious and are shown in

Figure 2.3.1.a

.

A true helix shape can be described as a three-

dimensional curve that travels along and sweeps

around an axis where any radial line remains

perpendicular to that axis.

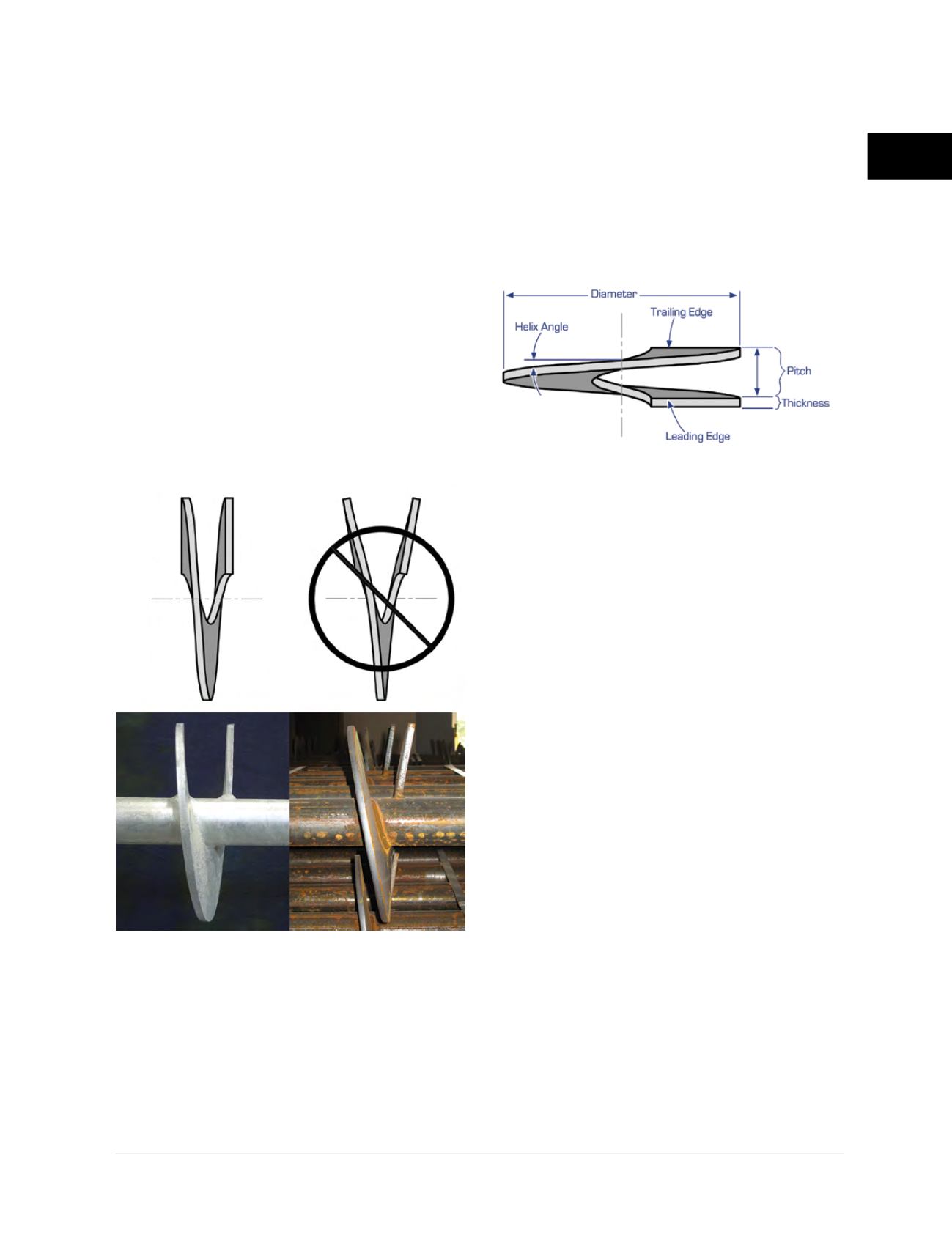

A helix plate is further defined by geometric

parameters including diameter, thickness, pitch,

helix angle and edge geometry

(Figure 2.3.1.b)

.

Helix plate diameters can vary from 6 to 16

inches for most commonly used shaft sizes. The

majority of helix plates have thicknesses of either

3/8

or

½

inch, however, thicker plates are used for

larger diameter piles. The pitch is the distance

or separation between the leading and trailing

edges and controls the depth of installation per

revolution of the helix plate. The helix angle is

the blade angle formed relative to the shaft and

will vary within the blade for any given radius.

The edge geometry refers both to the perimeter

geometry of the helix and the shape of the

leading and trailing edges. Most helix flights are

manufactured with a perimeter geometry that is

generally circular. The leading edge can have

varying cuts and shapes including blunt (flat),

sharpened, standard cut, V-style cut, etc. to

provide options for changing soil conditions. The

trailing edge is generally a standard cut, blunt or

sharpened, and has no effect on installation in

varying soils.

A helix plate is formed by cold pressing the

steel plate with matching machined dies. Both

the shape of the die and the amount of applied

Figure 2.3.1.a

Incorrect

Correct

Figure 2.3.1.b

Helix Plate Geometry