© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 17

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.4 Benefits

The use of helical piles in construction continues

to increase due to product and equipment

versatility and the various benefits that the

systems offer. Some of the benefits/advantages

of helical piles include:

•

High capacity deep foundation alternative

–

Allowable torque-rated capacities on the order

of 60 kips may be achieved with helical shaft

sizes up to 3.5 inches in diameter, as noted in

ICC-ES AC358 for conforming products. Even

higher capacities may be achieved with larger

shaft sections.

•

Predictable capacity

– With adequate

soil information and designer experience,

system capacities may be estimated very

closely to capacities determined from full-

scale load testing.

•

Lead sections and extensions can be

configured to achieve design depth and

capacity

– The design professional will

choose the helical pile shaft size and helix

plate configuration appropriate for the soil

conditions. Additional helix plates may be

considered on extensions when bearing in

weaker soils. Special “V-style” plates are

available to assist in penetrating dense soils.

•

Well-established torque to capacity

relationship

– Empirical torque factors

have been established through years of

product testing. Default capacity to torque

ratios are listed in ICC-ES AC358 for

conforming products.

•

All-weather installation

– Helical piles can

be installed through inclement weather and

freezing temperatures.

•

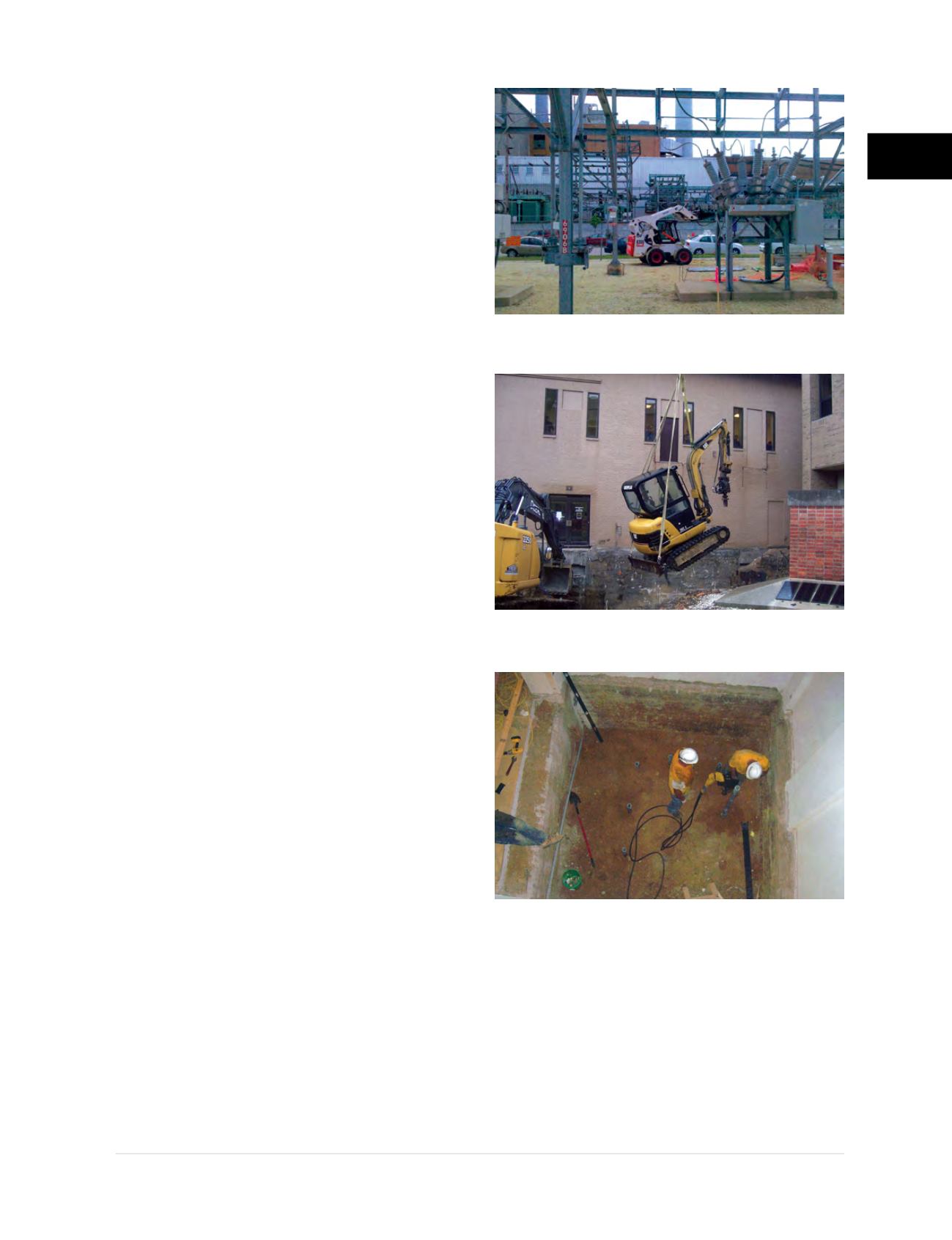

Installed in areas of limited or tight access

– Helical piles can be installed with hand-

held equipment, mini-excavators, skid steers,

backhoes and larger track equipment

(Figures

2.4.a1, 2.4.a2 and 2.4.a3)

. The equipment and

drive heads can be sized according to the

project design loads as well as site access.

•

Low mobilization costs

– Helical piles have

in part become a popular deep foundation

option because of the ability to achieve

moderate to high capacities, yet be installed

with smaller equipment. Mobilization costs are

then much lower than other deep foundation

alternatives, which in turn makes helical piles

an economical solution for many projects.

Figure 2.4.a1

Skid steer installing helical

piles within limited space at a substation

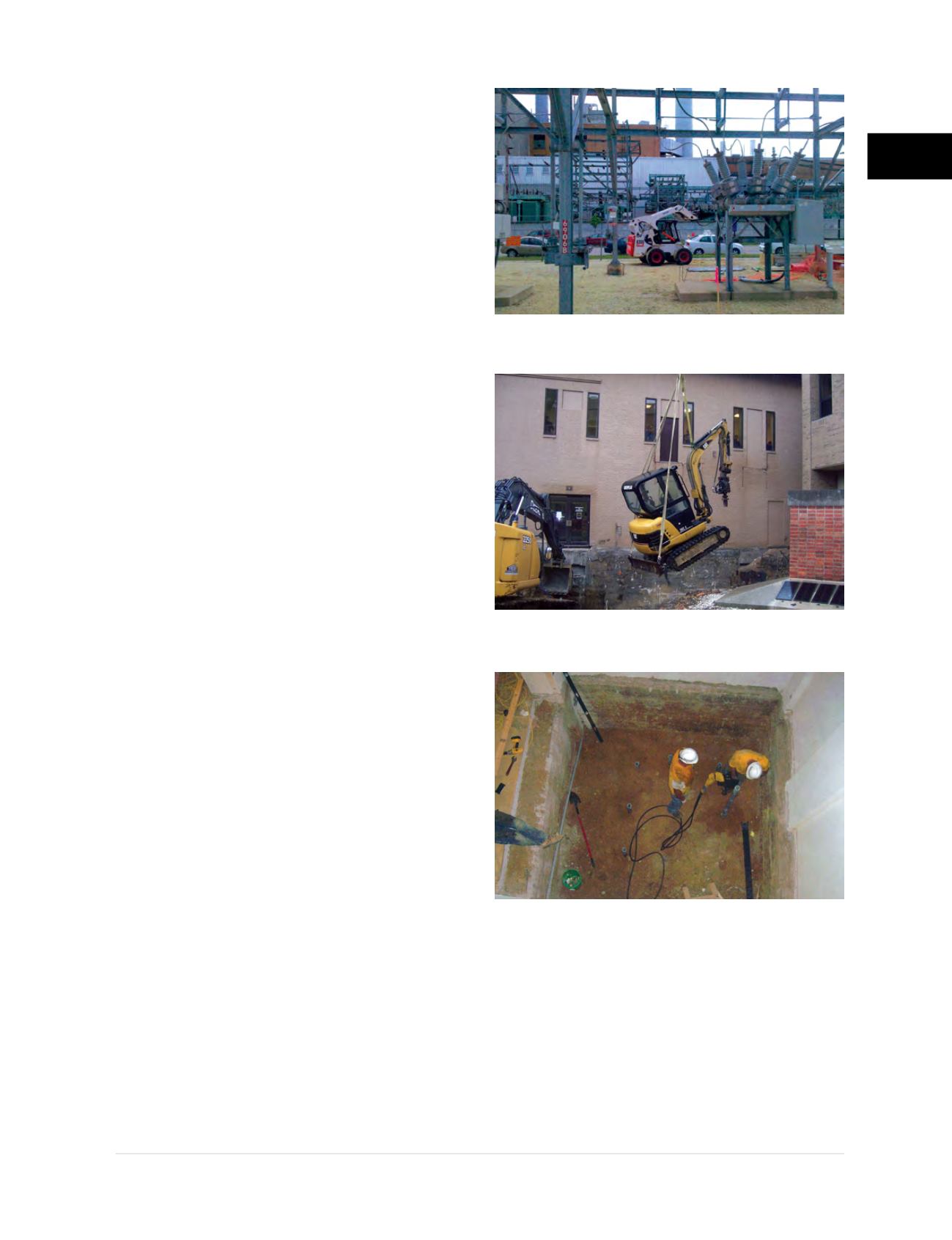

Figure 2.4.a2

Mini-excavator lowered by

crane into excavation to install helical tiebacks

Figure 2.4.a3

Helical piles installed with hand-held

equipment to support new elevator within existing school