© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 221

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

3.1. History

Commonly referred to as push piers, jacked

piles, resistance piers, or hydraulically driven

piers, these systems were developed to stabilize

buildings against further settlement and/or to

provide additional foundation support. Push pier

systems have patent history dating back to the

late 1800s and had their early beginnings in the

populated areas of the northeast United States

(US). Several inventors from New York were

the pioneers of these systems, and utilized a

common methodology of pushing hollow tubular

iron columns in sections to a suitable load bearing

stratum. They are considered retrofit systems

since they require an existing structure to provide

the reaction necessary to push or drive the piers

to competent soils. These early pier systems

were typically installed beneath opposing sides of

a building wall (staggered or in pairs), or directly

beneath the center of the wall.

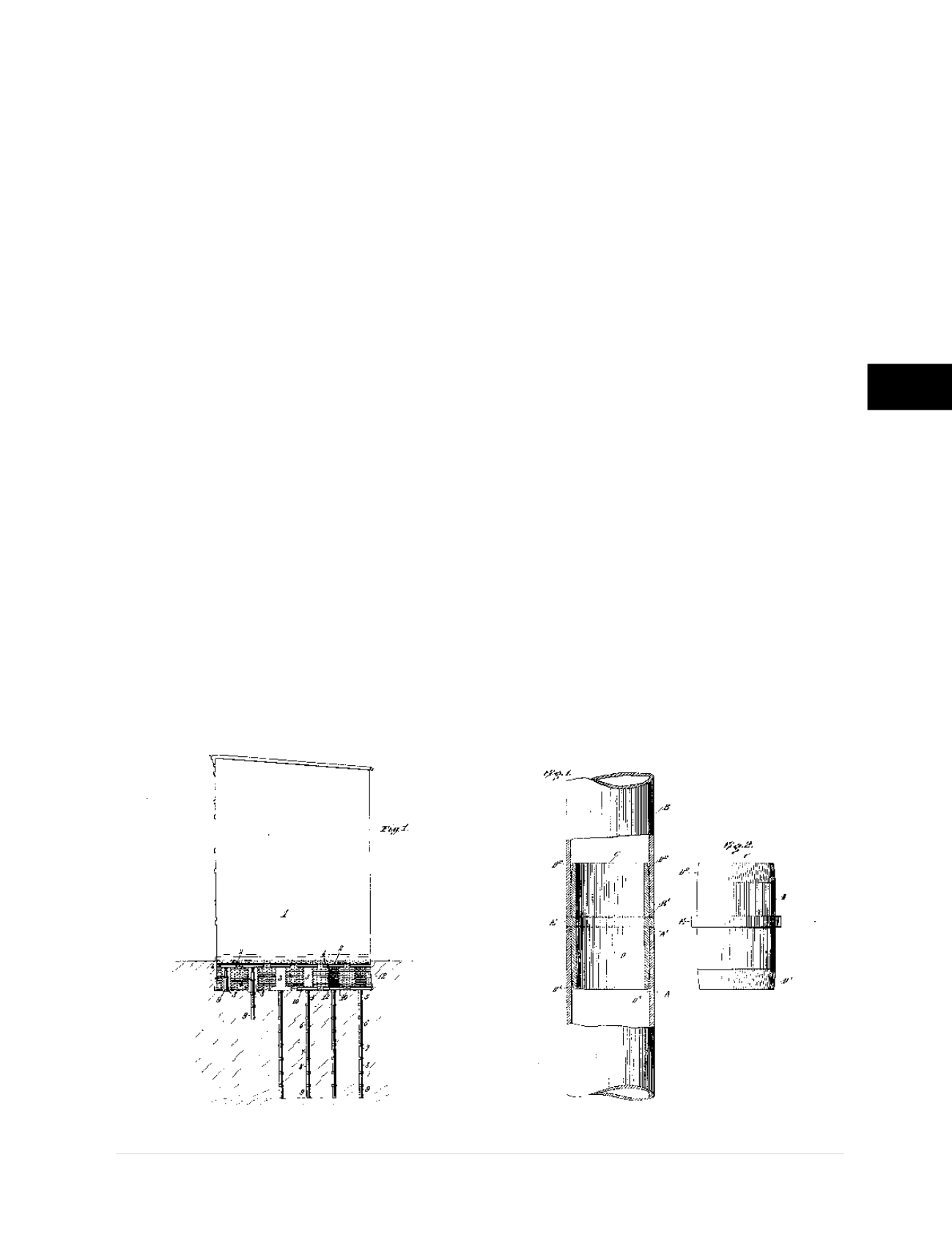

The first US patented push pier system was by

Jules Breuchard (US Patent No. 563,130) on June

30, 1896, which specified removal of portions of

brick foundation walls to allow for placement of

structural “headers” (stone or steel) and set up

of the drive equipment

(Figure 3.1.a)

. The drive

equipment or “ram” would push steel piling

sections using the weight of the structure until the

desired resistance was achieved. The top of the

pier would then be shimmed with brick or other

structural elements to another header beam across

the bottom of the foundation opening. The space

between the structural headers would then be

refilled with brick and mortar. The first application

of this system was in New York City in 1896. The

piers supported a 4-story building during the

excavation and construction of the basement

level of the new Commercial Cable Building on the

adjacent property. Nine piers were installed along

a 57-foot long wall to allow excavation to a depth

of about 10 feet below the underpinned structure.

The piers were manufactured from 10-inch outside

diameter (O.D.) pipe with a

5/8

-inch wall thickness.

Five-foot lengths of pipe were pushed to depths of

about 33 feet using a 60-ton jack to its full capacity.

External couplings were used to maintain direct

bearing of the pier sections. An internal coupling

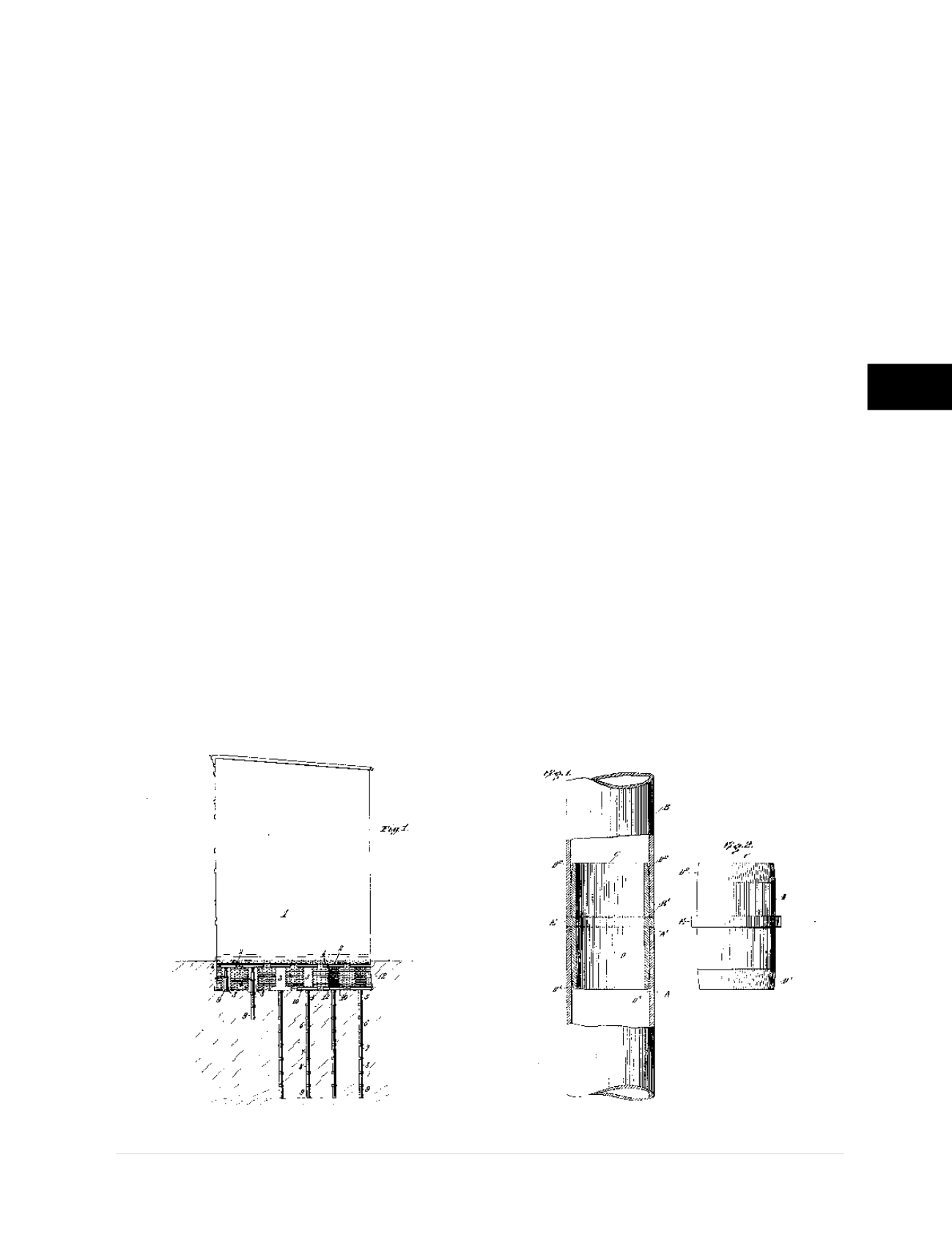

was first patented by Francis Pruyn (US Patent

No. 1,188,485) on June 27, 1916. This internal

coupling concept allowed for a pre-manufactured

connection with the same diameter as the pier

pipe

(Figure 3.1.b)

.

Figure 3.1.a

Breuchard patented system (1896)

Figure 3.1.b

Pruyn patented internal coupling (1916)