© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 231

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

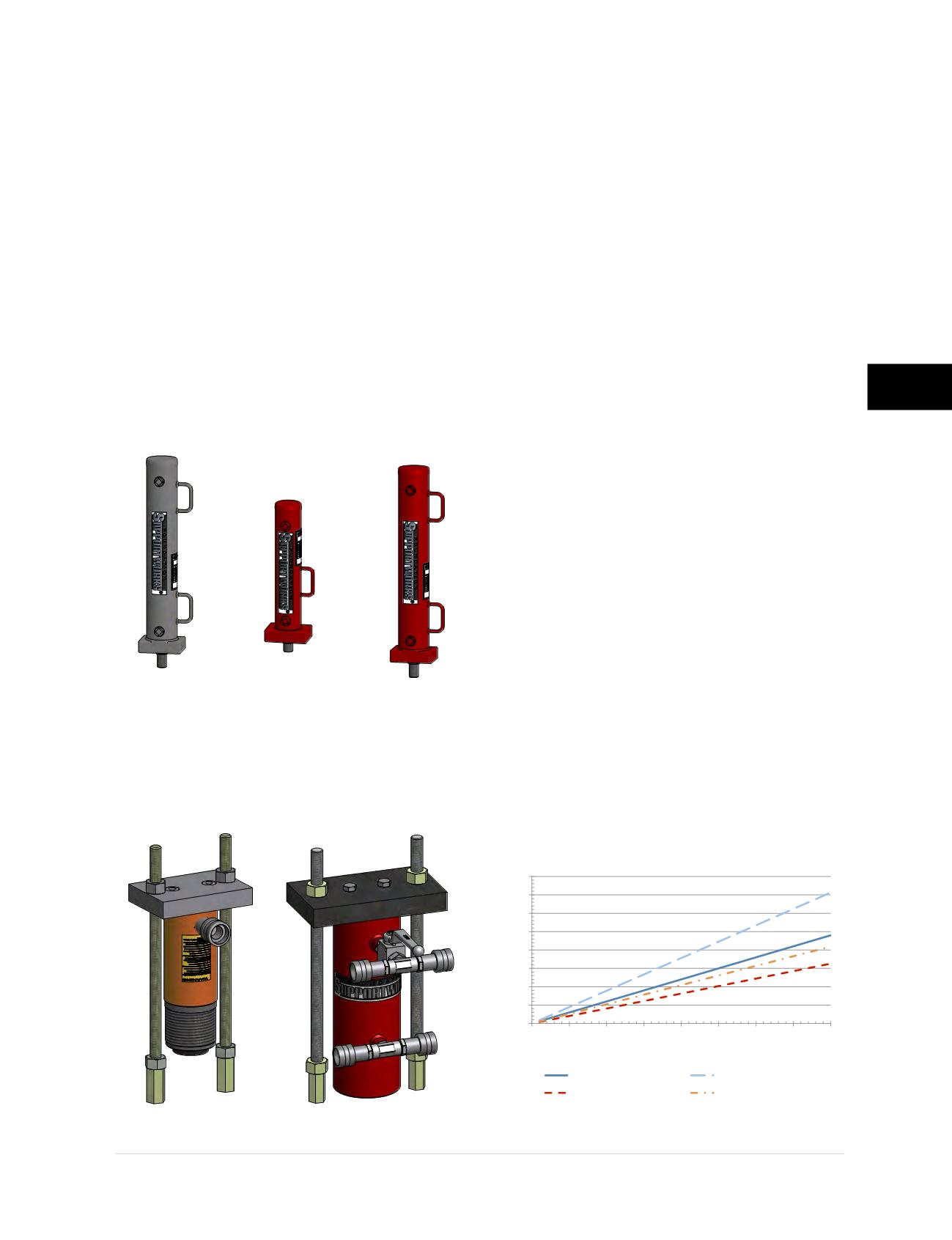

3.8.1 Drive and Lift Cylinders

Hydraulic drive cylinders (also commonly referred

to as “rams”) are used to push (drive) pier sections

below the existing footing until the target ultimate

pressure or load is achieved or until the structure

begins to mobilize (lift response). Hydraulic lift

cylinders are then used at each of the multiple

pier locations to provide the final lock-off load for

stabilization or to lift the structure, if required. FSI

offers three drive cylinder (FS425DC, FS35CSDC

and FS35DC) and two lift cylinder (FS256LC and

FS35LC) options. The FS35CSDC drive cylinder

is a shorter version of FS35DC for use in limited

headroom and crawl space applications. The FSI

drive and lift cylinders are shown in

Figures 3.8.1.a

and 3.8.1.b

. Drive and lift cylinder specifications

are provided in Appendix 3B (Drive Stand

Specifications) and Appendix 3C (Lift Assembly

Specifications), respectively.

3.8.2 Hydraulic Pumps

Hydraulic pumps used to drive pier tube

can be electric or gasoline powered. The

selection of the pump unit should take into

consideration the maximum drive pressure

(ultimate pier capacity) required and the rate

of pier installation desired. The flow rate of the

hydraulic pump will affect how fast piers can be

advanced with higher flow units allowing faster

pier installation. That said, gasoline pumps

generally provide greater flow than electric

pumps and are therefore preferred for deep

foundation pier installation. Electric pumps

are often recommended for the stabilization/

lift operation of foundation pier installation

and for both the driving and stabilization/lift

operations of slab pier installation. With lower

flow rates, electric pumps install piers slower

and provide greater control to reduce potential

overstressing of the concrete slab or footing

should sudden spikes in pressure/load occur.

FSI offers two models of electric pumps and

two models of gas pumps.

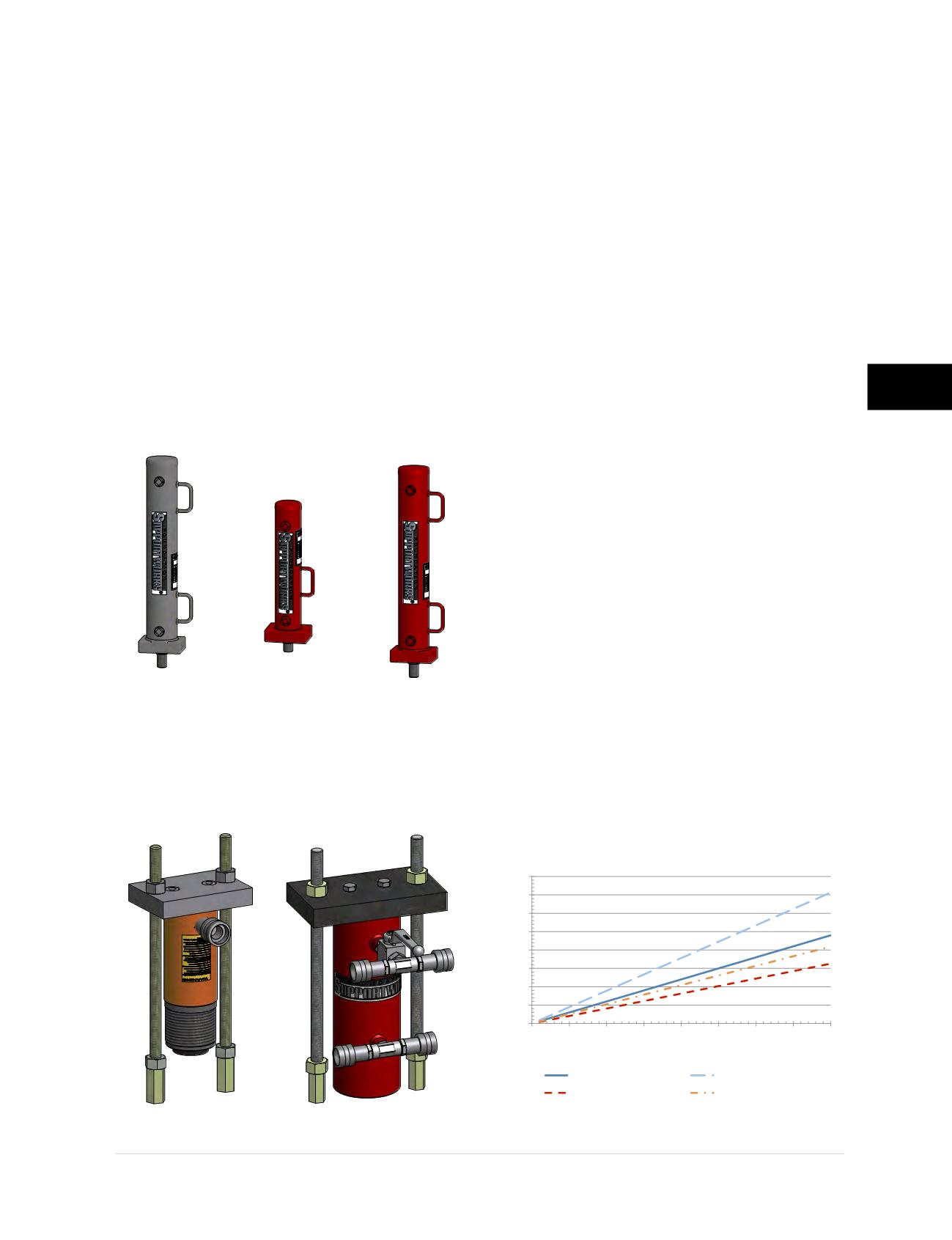

The effective area of the hydraulic drive cylinder

used will also have an effect on installation speed.

FSI drive cylinders FS35DC and FS35CSDC have

an effective area of 9.62 in

2

while operating in

extension mode and 6.48 in

2

while operating in

retraction mode. FSI drive cylinder FS425DC has

effective areas of 14.18 in

2

and 11.04 in

2

for the

extension and retraction modes, respectively.

With different effective areas, the drive cylinders

will have different extension and retraction rates

Figure 3.8.1.b

FSI lift cylinder assemblies. Left to

Right; FS238LCA (with FS256LC) and FS35LCA.

0

20

40

60

80

100

120

140

160

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

Extend or Retract Rate (inches/min)

Flow Rate (gpm)

FS35DC/FS35CSDC - Extended

FS35DC/FS35CSDC - Retract

FS425DC - Extended

FS425DC - Retract

Figure 3.8.2.a

FSI drive cylinder

extend and retract rates

Figure 3.8.1.a

FSI drive cylinders. Left to Right;

FS425DC, FS35CSDC and FS35DC (no relative scale).