© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 227

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

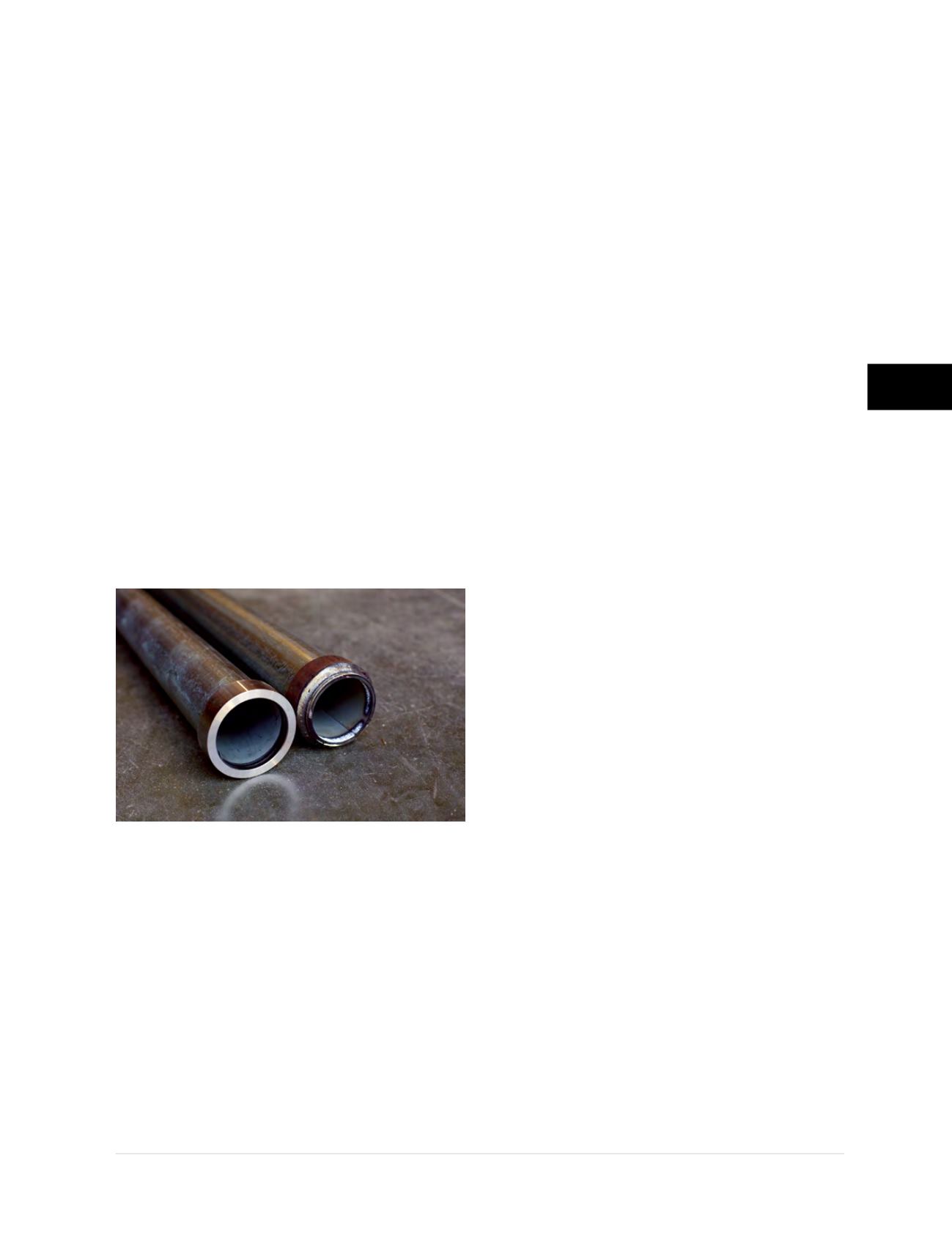

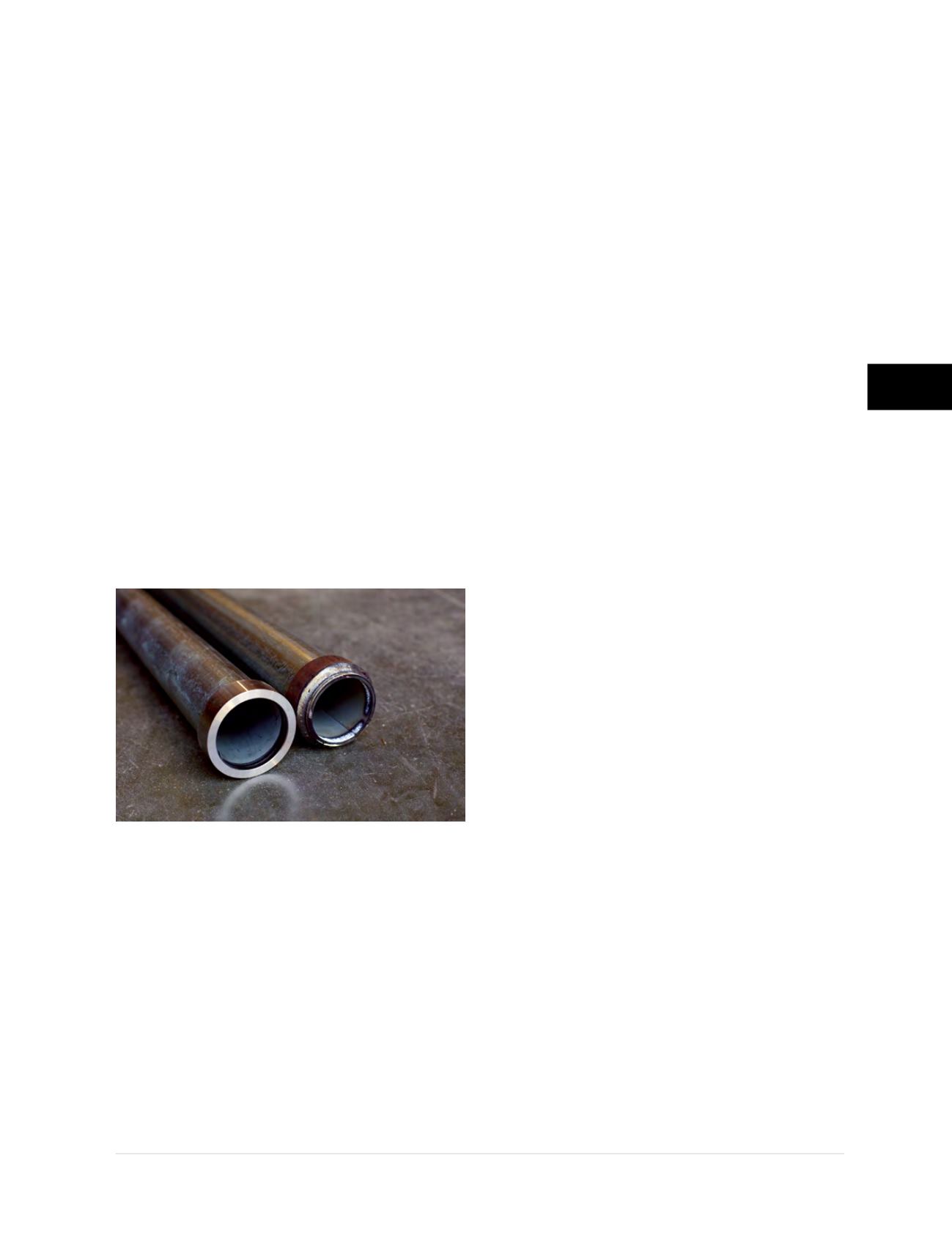

3.3.2.1 Friction Reduction Collar

A friction reduction collar is included at the

bearing end of push pier system starter tubes

(Figure 3.3.2.1.a)

. This collar consists of a 1-inch

long slice of a slightly larger round shaft section

slid over and welded to the end of the starter

tube, or a machined ring with a pressed fit.

These friction reduction collars have outside

diameters

1

-inch larger than their respective

pier sections and serve to either create annular

space or remold the soil around the pier shaft as

it is advanced through the soil. The reduction in

frictional resistance on the outside surface of the

pier results in a driven pier that generates most

of its capacity in end bearing. With reduced skin

friction and high bearing pressures generated

at the pier tip, push pier systems with friction

reduction collars also generally penetrate

deeper into the ground (than a frictional pier)

and advance through weak or marginal soils to

bear on competent material below.

It iscommontothinkofpushpiersasbeingadvanced

through overburden soils to bear on bedrock. This

may or may not be the case. For residential and

light commercial projects with light to moderate pier

loads, adequate resistance may be achieved within

very stiff to hard clay soils or medium dense to

dense sand and gravel. Allowable pier capacities of

15 to 20 kips, with a factor of safety of 1.5, may be

achieved in soils having standard penetration test

N-values around 30 blows per foot. Higher strength

soils or rock would therefore be required to develop

higher pier capacities.

The soils displaced or remolded by the friction

reduction collar “heal” back around and against the

shaft over time, generating an additional frictional

component to the pier’s capacity. This effect is

often referred to as pile “set up” when driving larger,

higher capacity pipe piles or H-piles. Set up can

occur within a matter of hours, days or weeks, and

is the reason piering contractors generally try to

start and finish installation of a push pier the same

day and, in some unique conditions, before a work

break is taken. Although this frictional capacity

can be significant, it is conservatively ignored in

most cases in the determination of the pier’s factor

of safety against settlement. The final drive force is

measured and documented prior to development

of the soils ultimate frictional resistance. Push pier

system factors of safety are further discussed in

Section 3.9.1.

3.3.3 Pier Tube

Pier tubes follow the starter tube during installation

and have a crimped or plug-welded slip-fit internal

coupling at the leading end (see next section). The

push pier tubes and couplings are manufactured

from hollow round structural steel sections.

Models PP237 and PP288 push pier tubes are

available in standard lengths of 18 and 36 inches.

The 18-inch long pier tubes are again used for

limited headroom or crawl space applications.

Models PP350 and PP400 pier tubes are available

in standard lengths of 36 inches only.

3.3.3.1 Coupling

Pier tube sections are coupled with an internal

slip-fit connection

(Figure 3.3.3.1.a)

. A hollow

round shaft section with an outside diameter

smaller than the inside diameter of the respective

pier tube is crimped (button-punched) or plug-

welded to the leading end. The internal coupler

extends one-half its length inside the pier

tube and one-half its length beyond the end

to maintain direct bearing of the pier sections.

The coupling is not pinned or bolted and is

therefore generally considered and utilized for

compression applications only.

Figure 3.3.2.1.a

PP288 starter tubes with pressed

fit and welded friction reduction collars