© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 20

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.6 Design Considerations

2.6.1 Spacing and Depth

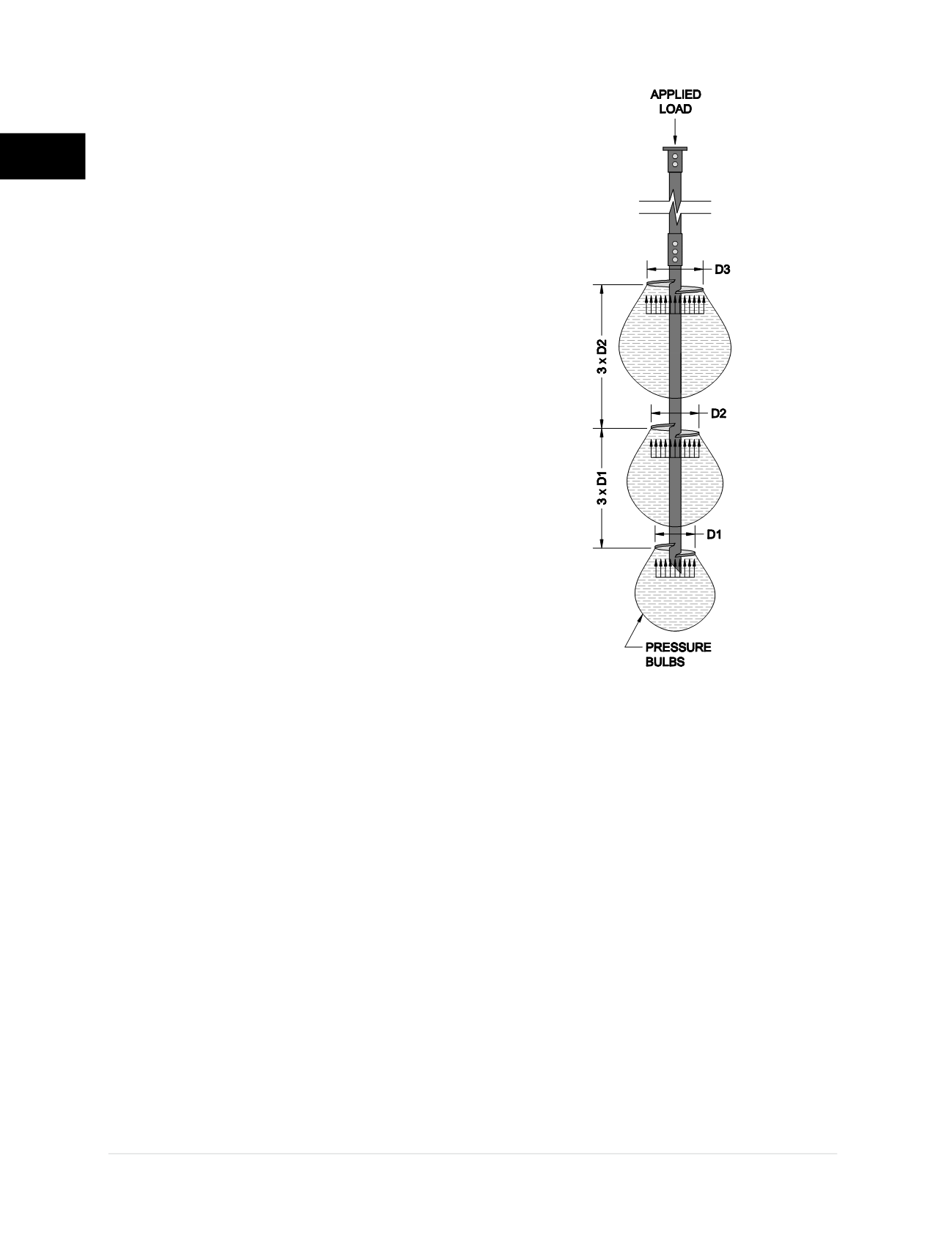

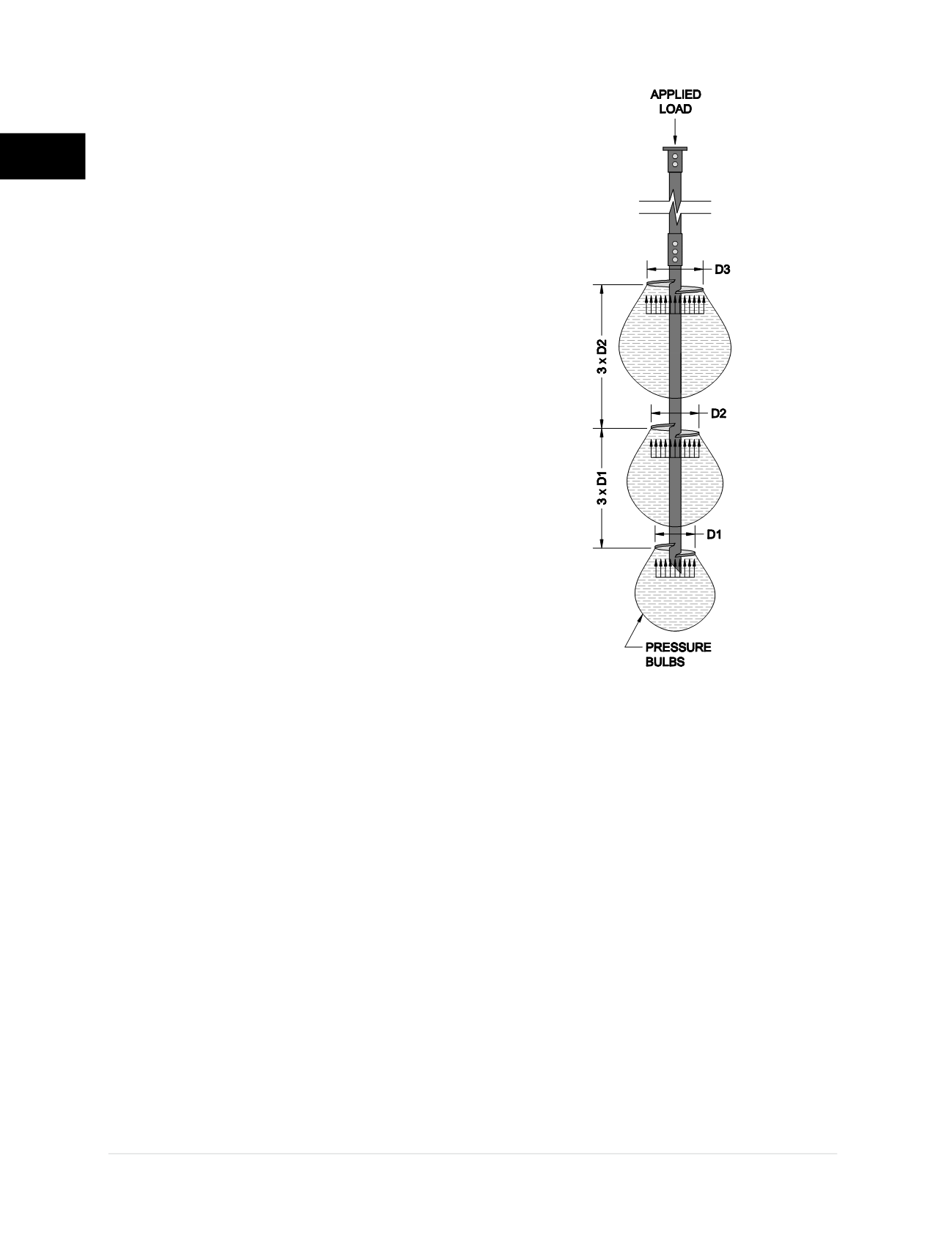

Helical piles are designed such that most

of the axial capacity of the pile is generated

through bearing of the helix plates against

the soil. The helix plates are typically spaced

three diameters apart along the pile shaft to

prevent one plate from contributing significant

stress to the bearing soil of the adjacent plate.

Significant stress influence is limited to a “bulb”

of soil within about two helix diameters from the

bearing surface in the axial direction and one

helix diameter from the center of the pile shaft

in the lateral direction. Each helix plate therefore

acts independently in bearing along the pile

shaft

(Figure 2.6.1.a)

. Helical piles designed with

helix plate spacing in accordance with AC358

could therefore use either the Individual Bearing

or Cylindrical Shear Methods of calculating

capacity. Helical piles manufactured with more

closely-spaced helix plates should consider the

Cylindrical Shear Method only. These design

methods are presented in Section 2.7.

Axially loaded helical piles shall have a center

to center spacing at the helix depth of at least

three (3) times the diameter of the largest helix

plate to avoid group efficiency effects (ICC-ES

AC358). The tops of the piles may be closer at

the ground surface, but the piles be installed at

a batter away from each other in order to meet

the spacing criteria at the helix depth.

The center to center spacing of laterally loaded

piles shall be at least eight (8) times the diameter

of the pile shaft at the ground surface and four

(4) times the diameter of the largest helix plate

measured at the plate depths (ICC-ES AC358).

If both of these criteria are not met, an analysis

should be completed to determine if there should

be a reduction in the lateral capacity per pile.

For tension applications, the uppermost helix

plate shall be installed to a depth at least twelve

(12) diameters below the ground surface (ICC-

ES AC358). Default torque correlation factors

(capacity to torque ratios) have been verified

for conforming systems tested and evaluated in

tension applications at and below these depths.

Design professionals may still determine that

shallower installations are appropriate for the

project given the site-specific soil conditions.

The uppermost helix plate shall be embedded in

the ground to a depth of at least five (5) diameters

to create a deep foundation bearing condition.

The upper helix plate shall also be located

below the depth of seasonal frost penetration

and below the “active zone”; i.e., the depth of

soil that undergoes seasonal volume changes

with changes in moisture content. The depth of

the uppermost helix plate would therefore be

determined from the greatest of these values.

Figure 2.6.1.a

Helix plate spacing with

bulbs of significant stress influence